What is a Diesel Generator

What is a Diesel Generator? A diesel generator is used to generate electric energy by using a diesel engine along with an electric generator (Alternator). A diesel generator can be used as an emergency power supply in case of power cuts or in places where there is no connection with the power grid. Power […]

Shindaiwa Diesel Welding Generators

Eco-conscious Diesel Welding Generators Shindaiwa Diesel Welding Generator are well-known for their light-weight, power and durability. Through an intelligent combination of components, Shindaiwa drive down your costs by delivering fuel efficient performance and super silent operation. Moreover, Shindaiwa has proven its technological capabilities in the development of engines with reduced emissions, complying with Singapore National […]

Uniquely Clark

What makes Clark forklifts special over other forklifts? Maintenance free Wet disc brakes Having a forklift equipped with wet disc brakes is a question that keeps coming up in the material handling industry. What are the benefits of a wet disc braking system in your forklift and what do these benefits give you? […]

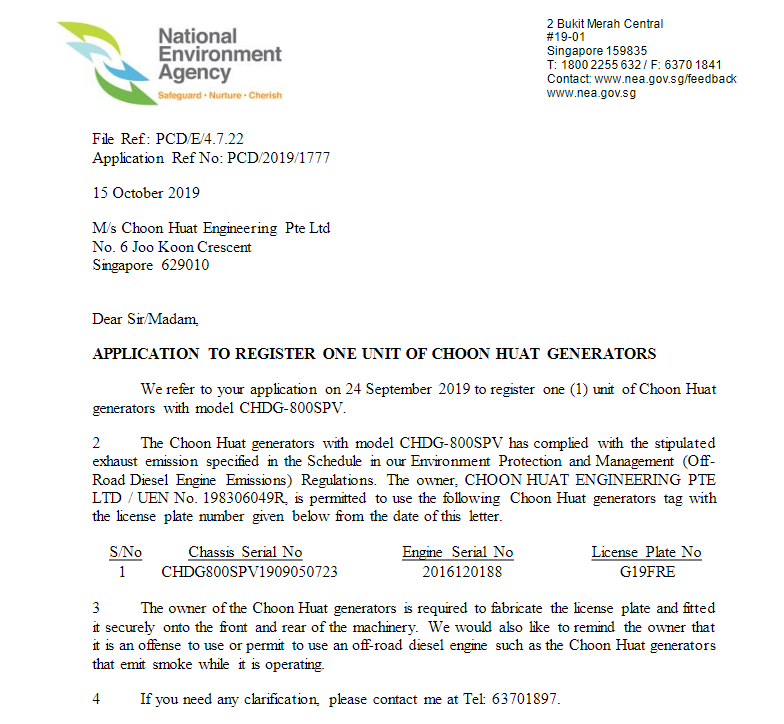

NEA LICENSE PLATE

NEA REGULATION ON OFF-ROAD DIESEL ENGINE Did you know it is now a requirement for off-road diesel engines to have an NEA approved license? The NEA website (2020, Air Pollution Regulations) states that “ Since 1 July 2012, under the Environmental Protection and Management (Off-Road Diesel Engine Emissions) Regulations 2012, all off-road diesel […]

What is welding?

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. Welding is distinct from lower temperature metal-joining techniques such as brazing and soldering, which do not melt the base metal. In addition to melting the base metal, […]